LED Replacement Light Bulbs

The humble incandescent light bulb has been around since the 1800’s and in simple terms consists of a thin wire filament that quickly glows

white hot when an electrical current is applied to it. Unfortunately most of the energy put into the filament is lost as heat and a very

small amount – approximately 10 – 12% is released as visible light, making it a rather inefficient product, but over time became quick and

simple to produce. The main developments in halogen and incandescent bulb technology has been alternative materials for the filaments which

has seen small improvements in efficiency.Currently several governments around the world have introduced measures to phase out of ban

incandescent bulbs and switch to more energy efficient alternatives. Venezuela and Brazil were the first countries to bring this phase out

in 2005 and there are now regulations being passed in the USA, Australia, Canada, Korea, Russia, Argentina and throughout Europe. In New

Zealand, moves to ban incandescent bulbs were first proposed by the Labour government in 2007, but at the time was seen as a step too far by

a government that at the time was seen as implementing too many “nanny state” policies. The other objections to the ban was the high cost

of efficient alternatives, the quality of light emitted from the phosphor coated lamps and the fact that compact fluorescents contained

small amounts of mercury – a potent neurotoxin.The bill was overturned by the incoming National party led government in 2008 and the

emphasis was placed on education through the EECA (Energy Efficiency Conservation Authority) and a voluntary shift to more efficient

lighting technologies.

So what are the alternatives to incandescent or halogen bulbs ?

Currently, there are two main choices for replacing or shifting to more efficient lighting technologies. Spiral wound compact fluorescent

bulbs (CFLs) and LED equivalents.

Compact fluorescent bulbs – CFL’s

The first alternative to incandescent bulbs – the spiral would compact fluorescent lamp used a thin glass tube coiled in a spiral shape and

filled with a small amount of Argon gas and mercury vapour. An electrical current is applied by way of an internal ballast that excites the

gas molecules inside which in turn produce a light on the UV (ultra violet) spectrum. The ultra violet light then passes through a phosphor

coating on the inside of the spiral wrapped glass which changes the wavelength of the light so that it is emitted on the visible spectrum.

CFLs used approximately 50 – 60% less energy than incandescent light bulbs , but do had several negative factors that prevent them from

becoming the light source of choice.

Slow start up time – unlike an incandescent that reaches full output virtually instantly, the first generation of CFLs took up to 10 seconds

to reach full brightness. Developments in ballast technology have reduced this start up time, however they still take time to warm up and

are not an “instant on” source of light.

Flickering causing headaches – while virtually impossible to see with the naked eye – the first generation of CFL ballasts

refreshed themselves at a rate of 50/60 times per second (our power cycle in NZ is 50 Hz) and there were complaints about this flickering

causing headaches – modern CFL ballasts refresh at a rate of 10,000 time per second. However recent research has shown that CFLs can emit

radio frequency radiation that can cause headaches, fatigue or dizziness

Light quality – the first generation of CFLs were produced in a 5000k “cool white” colour, or a “cooler” light than the

incandescent, however now they are available in a range of colour temperatures including 2700k – 3000k warm white. However the other issue

with light quality came down to the fact that the original light fittings were designed for the way an incandescent bulb emitted light – the

fittings reflectors were designed to capture as much of this light as possible and direct it to where it was required. Many modern light

fixtures have been designed for use exclusively with compact fluorescents and have had their internal reflector design changed to suit.

Mercury content – while the amount of mercury in a CFL is very small – between 3 – 5 micrograms, there is still potential

to release this into a home if a bulb is broken. The mercury is released as a vapour but quickly turns into a liquid that can stick to dust

or surfaces – (the safe recommended maximum level of mercury ingestion is about 0.1 microgram per kg of body weight per day). By comparison

fish products can contain up to 175 micrograms of mercury per kg. Smaller fish contain lower content of mercury – however as they are eaten

by larger fish, their mercury content is increased – and over 40% of this mercury in fish is released by coal fired power plants into the

atmosphere. Even when you take into account the disposal of millions of CFLs in landfills each year, CFLs still help reduce mercury release

into the environment as the energy saved from them results in less emissions from coal fired power. Still there is a better alternative than

putting more mercury back into landfills !

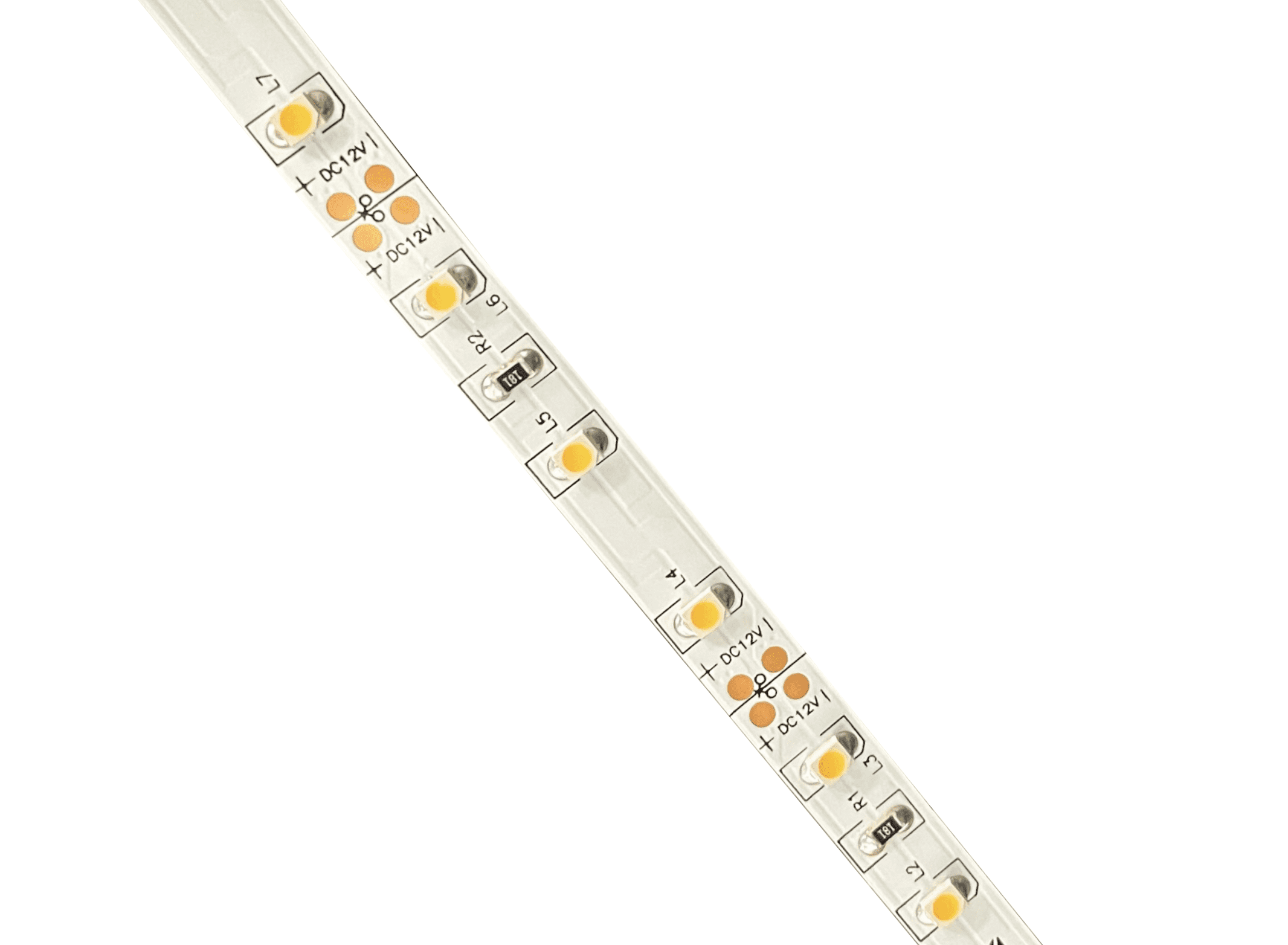

LEDs – Light Emitting Diodes are not a new technology

First developed in the 1950s and used primarily as indicator lights due to their low output and long life (originally quoted at 100,000

hours) The last 10 years have seen rapid development in LED technology with their light output now reaching up to 130 lumens per watt –

compared to the 12 lumens per watt achieved from modern incandescent lamps, resulting in energy savings of 80 – 90% for an equivalent amount

of light – you can power 10 LED lamps for the same cost as 1 incandescent ! Because LEDs work with direct current (DC) there is no visible

flicker and they also do not emit radio waves like CFLs. The other advantage of an LED light bulb is its long life – while this was

originally claimed at 100,000 hours (and most likely correct due to their low power and low operating temperature), most quality LED

replacements are rated at between 25,000 -30,000 hours – that’s still 5 to 8 times longer than a traditional bulb. The reduction in rated

life time is mainly due to the effects of heat – the hotter an LED operates, the less time it will last, and unfortunately as the output per

watt has increased, so too has the operating temperature. This is why the heat sink design or an LED bulb is an important feature and it

takes that heat away from the diode itself.

Cost of LED bulbs – originally LED bulbs sold for in excess of $70 for a quality unit with a good light output – however

were still only really suitable for replacing 20 – 30 watt lamps, however this has decreased significantly in the last few years with

quality LED replacements starting from as little as $14. While this is still significantly more than the cost on an incandescent – based on

10 hours per day running, the LED will save $30 in power costs per year and pay for itself within 6 months and save up to $300 or more over

its rated life.

Better for the environment – LED bulbs do not contain lead or mercury, the aluminium bodies and acrylic lenses are

virtually bombproof – so even if you do manage to break one, they do not require any special clean up procedures. Also the reduced load on

the national power supply will also reduce our need for coal fired power plants – resulting in lower mercury and CO2 emissions into the

environment.

LEDs have now reached a point where they are becoming the go to choice for alternative replacements of halogen and incandescent lighting

technologies, they are both affordable with a short return on investment and bright enough to truly replace the incumbent technology while

minimising our effect on the planet and should be a first choice of anyone looking at saving themselves money and helping to do our bit for

the environment.

See our full range of LED Replacement Light Bulbs

.png)

.png)

.png)

.png)

.png)

.png)

.png)